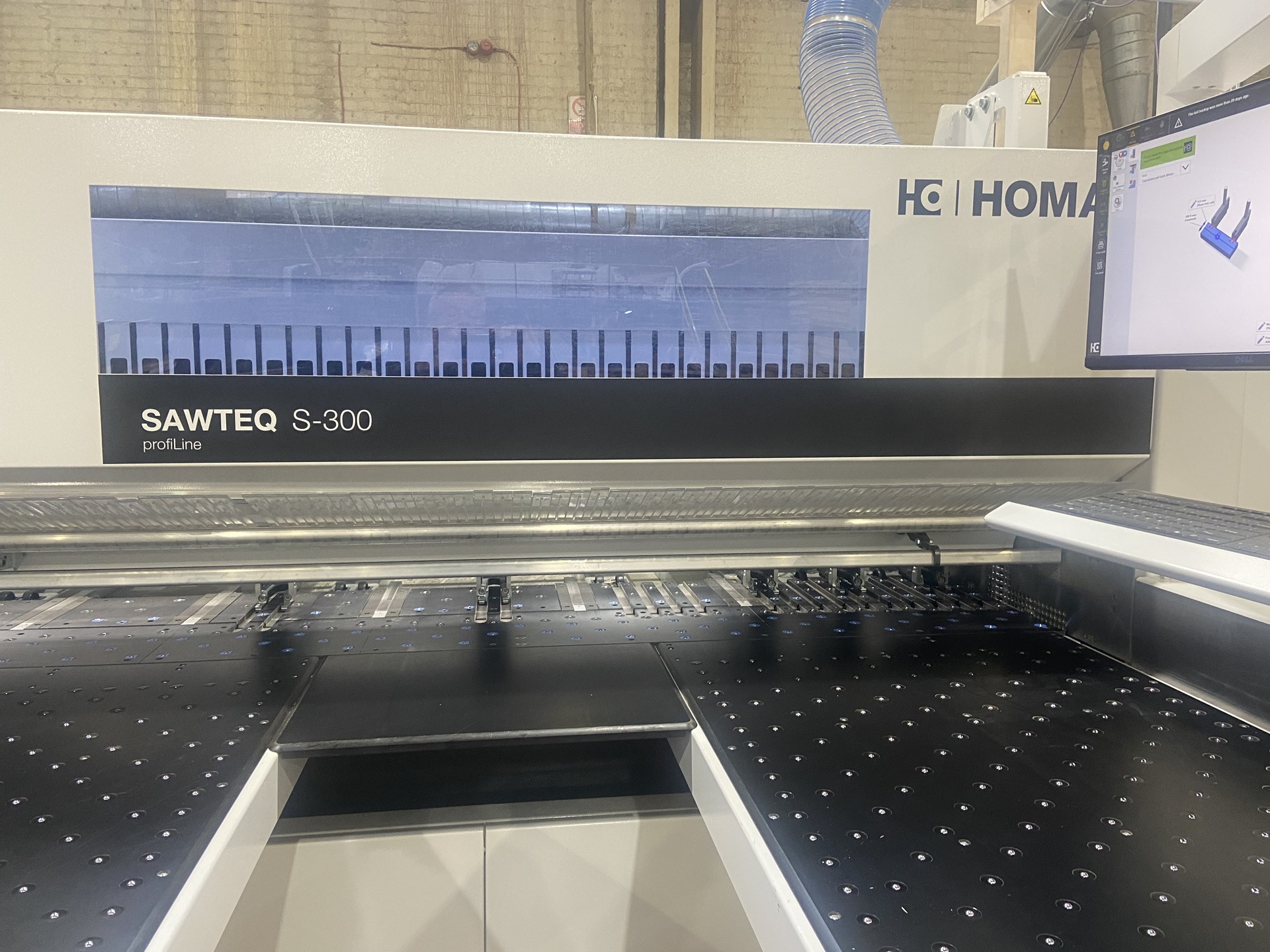

14 Feb Our New HOMAG SAWTEQ S-300 Beam Saw

Crocodile Packaging is thrilled to announce a significant enhancement to our production capabilities with the installation of a new state-of-the-art HOMAG SAWTEQ S-300 beam saw. This investment underscores our commitment to delivering unparalleled precision and efficiency in our panel cutting service operation, solidifying our position as a leader in the Southwest’s woodworking industry.

The HOMAG SAWTEQ S-300, renowned for its German engineering excellence, and is equipped with the advanced CADmatic 5 control software. This integration ensures intuitive operation and exceptional cutting accuracy, allowing us to handle sheet materials up to 3,800 mm in length. Such capacity makes our facility one of the most capable in the region.

Diverse Material Handling

Our new beam saw enables us to efficiently process a variety of materials, with a specialisation in Plywood and Oriented Strand Board (OSB). Whether your project demands high-volume production or is a 1off bespoke project, our team is equipped to meet your specific requirements. We offer flexibility in material sourcing and stock a variety of plywood and OSB boards so can provide sheet materials as needed or work with free-issue materials supplied by our customers.

Unmatched Precision and Quality Control

At Crocodile Packaging, precision is paramount. Our saw production team comprises four certified HOMAG trained saw technicians dedicated to delivering cutting accuracy within a tolerance of ±0.2 mm. To maintain this high standard, we implement continuous quality control measures throughout the cutting process. The SAWTEQ S-300’s blade condition monitoring system alerts us when blade changes are necessary, ensuring consistently clean and precise cuts for every project.

Value-Added Services

Beyond cutting, we offer comprehensive post-production services to streamline your operations. Our team can handle stacking, binding, and shrink-wrapping of your materials, utilizing either your shipping pallets or ours, based on your preference. Given our extensive experience in shipping crate and pallet production, we are well-equipped to manage these tasks efficiently, adding value to your supply chain.

Commitment to Sustainability

In line with our dedication to environmental responsibility all unusable offcuts and sawdust from our cutting operations are fed into our biomass boiler system which then heats our factory. This is just one measure that Crocodile employs to promote sustainable production shipping practices by minimising waste.

About Crocodile Packaging

With over 30 years of experience, Crocodile Packaging UK has evolved from a family-run business into an industrial packaging leader. We specialize in manufacturing wooden based shipping crates tailored to specific sizes, including our unique clipped flat-packable system which offers a unique sustainable and reusable packaging solution. Our products are all designed for easy storage, maintenance and reuse, aligning with our commitment to environmental stewardship.

Connect with Us

We invite you to experience the enhanced capabilities of our new beam saw. For inquiries or to discuss your project needs, please contact us at enquiries@crocodile.uk.com. Our team is committed to responding promptly, ensuring you receive the information and support you need within one working day.

This investment in the HOMAG SAWTEQ S-300 reflects our ongoing dedication to providing superior service and quality to our clients. We look forward to leveraging this advanced technology to meet and exceed your expectations in all your panel cutting and packaging needs.