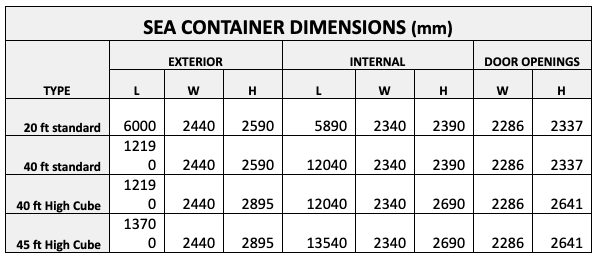

The two most common sea container external dimensions are 20’ (6.0m) and 40’ (12.0m) in length, always 8’ (2.4m) wide and with a standard height of 8’6” (2.59m)

High Cube containers are slightly higher at 9’6” (2.9m)

All containers can be transported by road.

Shipping a container by sea can be an expensive business and it is important that the internal capacity is optimised in order to help minimise unit shipping costs.

When packing a container, the most important dimensions to be aware of for oversized export packing are the internal dimensions, as well as the door opening sizes.

The table below shows a summary of the dimensions for the common Container sizes.

Optimising Capacity for Sea Container Shipping

When using packing crates for sending by sea it is common for a product to be too big or too small for standard sized crates which can lead to wasted space within a container. Spending time calculating the best sized packing crate can lead to big rewards by making the most of the internal volume available within a container.

Crocodile Export Crates for Sea Freight Containers

Custom export crates can be made to any dimension which means that not only can a crate be made to exactly fit a product but use of the internal space within sea freight containers can be optimised, driving down the unit cost of exporting products.

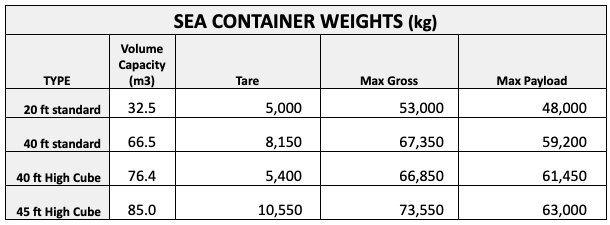

Sea Container Weights

Sea containers are made to exacting global standards and therefore they are subject to restrictions on weight, not only with regards to road haulage but overall wight for shipment by sea.

Weight information is clearly marked on each container:

- TARE: This is the weight of the container when empty.

- MAX GROSS: This is the total MAXIMUM weight allowed, including it’s own weight.

- MAX PAYLOAD: This is the maximum weight of cargo permitted within the container.

See below a summary of weight information for the common container sizes:

Packaging containers

The safe stowage and securing of cargoes are critical to the safety of life at sea as well as ensuring that any product damage is minimised.

Poor loading practices have led to numerous ship casualties and have caused injury and loss of life both at sea and during on-shore activities.

Poor weight distribution and shifting cargoes have also caused losses of whole containers during transit – more than 500 sea containers per year are lost in this way.

More Information on Sea Freight Containers

See below for links to advice, codes of practice and rules & regulations that relate to loading & packing sea freight containers:

- Hazardous goods

- International shipment of timber packaging & products (ISPM15)

- Weight distribution both within each container and when loaded onto container ships.