Looking to understand more about crate parts? Then why not learn from the best!

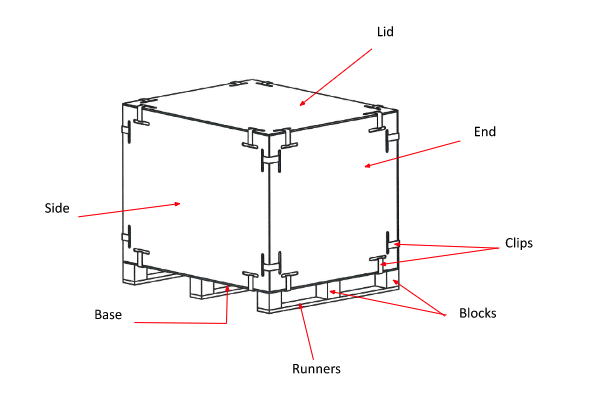

The diagram shows the various key components that make up a standard Crocodile crate that we produce every day as one of the UK’s leading shipping crate manufacturers.

Whilst the dimensions, clipping pattern and pallet arrangement may change, the key components will remain the same. The following is how we refer to them.

Parts of a Crate

- LID

This is obviously the top of the crate and usually the same thickness as the other panels.

The lid will have a rebate around its entire perimeter.

- SIDE

We call the longer of the panels the Side.

The side panels are easily identifiable as they have two rebates. One at each end.

- END

The shorter of the panels is known as the End

The end panels do not have any rebates.

- BASE

The bottom of the crate is known as the Base (sometimes as the Deck)

Like the lid, the base panel will have a rebate all the way around.

- BLOCKS & RUNNERS

The pallet arrangement is always an integral part of the Crocodile crate.

The most common pallet arrangement is to use Block & Runners. These usually consist of Presswood blocks joined with plywood runners. Presswood is an engineered material created from wood waste and is exempt from ISPM15 shipping regulations.

- CLIPS

Clips are manually inserted into machined slots on the panels, and whilst the rebate system provides high levels of strength to prevent the crate collapsing inwards, the spring steel Crocodile clips prevent the sides & lid from bursting outwards. There are options for standard or heavy duty clips and the number of clips used will depend on crate size, shipping methodology and nature of contents.

Contact Us for Wooden Crate Packaging

Need wooden crate packaging for international shipping? We are a leading UK supplier of bespoke wooden crates made to order. Contact us to find out how we can help your logistics team.